Technology

We have launched one of the most modern production lines for functional films in Europe.

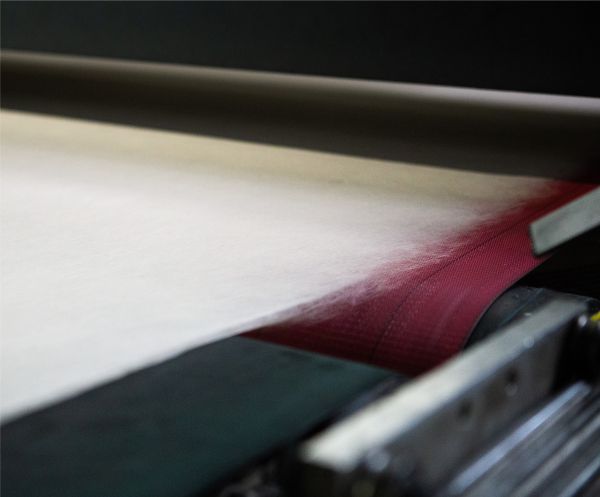

We have launched one of the most modern lines for the production of PP / PE functional films in Europe, using the casting technology (CAST), with a module for longitudinal stretching of the MDO film (Machin Direction Orientation).

The layer of such a film provides resistance to sunlight (including UV), water penetration and regulates the balance of water vapour flow through the roof system. High quality of the breathable internal functional layer determines the durability of our highly vapour-permeable COROTOP® membranes, both during construction works and during their exploitation.

MAX. EFFICIENCY 500 kg/h

AVAILABLE BASIS WEIGHTS 18-70 gsm

NOMINAL FILM WIDTH from 1030 to 1630 mm

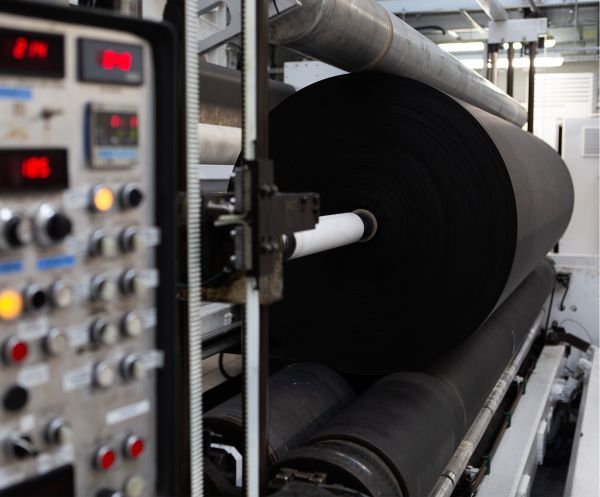

Production of nonwovens

Our machine park is equipped with a line for the production of PP nonwovens using the SPUNDBOND method, which plays an equally important role in the membrane. Non-woven fabric protects the functional film, ensures the resistance of the membrane to mechanical and weather conditions.

We use thermal or adhesive lamination in the membrane production process. We use our nonwovens not only for the production of membranes or vapour barrier. They can also be used in the medical and furniture industries.

WEIGHT RANGE approx. 20 – 200 g / m²

Laboratory

Our own well-equipped laboratory allows us to control the quality of both raw materials and materials during the production process and the finished product. A qualified team verifies that each product meets even the smallest requirement of standards and certificates. The possibility of testing parameters allows us to maintain the quality of our products at the highest level.

Certificates

Our membranes are subject to additional tests apart from standard ones carried out in accordance with the guidelines of harmonised standards. High requirements set by individual certification units are not problematic for us.

In order to maintain the highest standards of the product subject to certification, we care about the constant quality of the production technology. This is facilitated by audits verifying the continuity of the certified product quality.